Known for its adhesive and cohesive assets, bitumen is mostly utilised in the construction industry. Bitumen is applied on road paving because it is viscous when hot, but solid once it cools down. Therefore Bitumen operates as the binder/glue for pieces of the aggregate.

The vast majority of refined bitumen is used in construction: primarily as a constituent of products used in paving and roofing applications. According to the requirements of the end use bitumen is produced to specification. This is achieved either by refining process or blending.

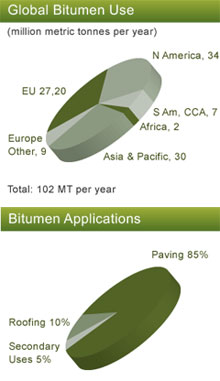

It is estimated that the current world use of bitumen is approximately 102 million tonnes per year. Approximately 85% of all the bitumen produced is used as the binder in asphalt for roads.

Bitumen is applied in construction and maintenance of:

- Highways,

- Airport runways,

- Footways / Pedestrian Ways,

- Car parks, Race tracks,

- Tennis courts, Roofing,

- Damp proofing,

- Dams Reservoir and pool linings,

- Sound proofing,

- Pipe coatings,

- Cable Coatings,

- Paints, Building Water Proofing,

- Tile underlying water proofing,

- Newspaper Ink Production,

- and many other applications

In order realize the complexity of bitumen as a product an in-depth knowledge and detailed understanding for one of the way the roads are built is crucial. Specialists in bitumen know bitumen as an advanced and complex construction material, not as a mere by-product of the oil refining process. The ultimate paving material (also referred to hot mix asphalt concrete – HMAC or HMA) consists of about 93 – 97% mineral aggregate (stone), sand and filler. The remaining percentage is bitumen.